.png?width=927&height=1163&name=FT752-series-cropped%20(1).png)

Hard anodised aluminium wind sensors

The compact size of FT7 Series wind sensors allows for efficient power usage, making them easy to heat and keep ice-free. Equipped with a thermostatically controlled heating system, they are ideal for extreme cold conditions, operating down to -40°C and throughout severe icing events. As tough anemometers constructed from hard-anodized aluminium and subjected to over 30 environmental tests, FT7 Series wind sensors are built to withstand harsh conditions. They are highly resistant to corrosion, sand, hail, solar radiation, and bird strikes, and are sealed to IPX6K, IP66, and IP67 standards. Additionally, they are MIL-STD-810G rated for anti-icing.

Benefits

From initial goods inspection to calibration and testing, quality is at the heart of FT Technologies’ manufacturing principles. FT is ISO 9001 and ISO 14001 accredited and adheres to APQP4 Wind for new product development.

Reading wind speeds from 0 to 90m/s and outputting data at 10Hz, FT’s unique acu-res® technology gives you precise wind measurements with no delay.

Hard-anodised aluminium, waterproof housings, industrial-grade connectors, and all-body heating ensures FT wind sensors provide reliable wind speed and direction data, even in extreme conditions.

Features

-

WIND SPEED 0-90 m/s

-

WIND ANGLE 0-360 degrees

-

TEMPERATURE -20 to + 60° C

- PRESSURE 260 to 1260 hPa

- COMPASS (FT743-SM)

- Hard anodised aluminium body is corrosion resistant to ISO9227 & IEC12944, corrosion class C5M

- Powered by Acu-Res® Technology – gives a signal 40dB stronger than other ultrasonics

- Acu-Res® Technology - wind readings unaffected by shock and vibration

- Acu-Res® software automatically compensates for changes in air temperature, pressure and humidity

-

No moving parts, maintenance free

-

Compact size and shape make it physically strong

-

Thermostatically-controlled heating system – ideal for use in extreme environments

-

Fully-sealed and waterproof to IPX6K, IP66 and IP67

-

Shock-resistant, immune to vibration, electromagnetic interference and solar radiation

-

Operates at temperatures between -40°C and +85°C

-

Resists icing conditions to MIL-STD-810G

-

Operates at altitudes up to 4000m

-

No exposed parts – resistant to bird attack

-

Low power usage – even when heated

-

Wind speed can be output in m/s, km/h or knots

-

Available with digital RS485HD or analogue 4-20mA interface

-

Individually calibrated in our wind tunnel, no re-calibration required

-

Calibration results traceable by serial number, report available upon request

For specifications, please see our datasheets

Accessories

FT001 – 15m Cable for Digital Wind Sensors

FT004 – 8m Cable for Analogue Wind Sensors

FT005 – 15m Cable for Analogue Wind Sensors

FT007 – 5m Cable for Digital Wind Sensors

FT008 – 5m Cable for Analogue Wind Sensors

FT009 – 1.5m Cable for FT74X-SM

FT027 – O-Ring for FT742-DM

FT028 – O-ring for Pipe Mount sensor (3.53 CS x 34.52 ID)

FT029 – O-Ring for FT74X-SM

FT031 – 25mm (1″) Size Adaptor Kit for FT742-DM

FT032 – 50mm (2″) Size Adaptor Kit for FT742-DM

FT033 – Tapered Pipe Insert for FT742-DM

FT034 – Self-Locking Fastener for FT742-DM

FT035 – Grounding Spring for FT742-DM

FT036 – Tapered Pipe Insert for DM50 sensor (48.3mm OD)

FT037 – Self-locking Fastener for DM50 sensor

FT039 – Alignment Collar for DM50 sensor

FT040 – Mast Mounted Alignment Accessory for DM50 sensor

FT041 – Sensor Mounted Alignment Accessory for DM50 sensor

FT044 – Grounding Spring replacement kit for DM50 sensor

FT054 – Acu-Test Pack (Digital)

FT055 – Acu-Test Pack (Analogue)

FT058 – Acu-Test Pack for FT74X-SM (RS422)

FT059 – Acu-Test Pack for FT74X-SM (RS485HD)

FT062 – 24VDC Power Adaptor

FT090 – Pipe Mount Adaptor

FT909 – Cold Shrink Boot

V064 – Female Connector for Analogue Wind Sensors

V086 – Female Connector for Digital Wind Sensors

Certifications

Environmental Tests

EN 60068-2-1: Cold

EN 60068-2-2: Dry Heat

EN 60068-2-14: Temperature Cycling

EN 60068-2-30: Cyclic Humidity

EN 60068-2-78: Stationary Humidity

EN 60068-2-38: Combined Temperature & Humidity

EN 60068-2-6: Sinusoidal Vibration

EN 60068-2-64: Random Vibration

EN 60068-2-27: Mechanical Shock

EN 60529: IP 6X Dust

EN 60529: IP X7 Immersion

ISO 20653:2013: IPX6K High Velocity Water Jets with Increased Pressure

DEF STAN 00-35 Issue 4: Wind Blown Dust Test

DEF STAN 00-35 Issue 4: Wind Blown Sand Test

ISO 9227 & IEC12944: Corrosion

EN 60068-2-5: Solar Radiation

EN 60068-2-13: Altitude

EN 60068-2-31: Drop

EN 61215: Hail

DEF STAN 00-35: Fog

DEF STAN 00-35: Rain

MIL-STD-810G: Icing

HALT: Halt

EMC

EN 61000-6-3: Emission standard for residential, commercial and light-industrial environments

EN 61000-6-2: Immunity for Industrial Environments

EN 61000-4-2: Electrostatic discharge immunity test

EN 61000-4-3: Radiated, radio-frequency, electromagnetic field immunity test

EN 61000-4-4: Electrical fast transient/burst immunity test

EN 61000-4-5: Surge immunity test

EN 61000-4-6: Immunity to conducted disturbances, induced by RF fields

EN 61000-4-8: Power frequency magnetic field immunity test

EN 61000-4-9: Pulse magnetic field immunity test

EN 61000-4-10: Damped oscillatory magnetic field immunity test

EN 61000-4-29: Voltage dips, short interruptions and voltage variations on d.c. input power port immunity tests

If you want to know more about FT wind sensors certification, visit the Product Certification page.

Applications

With industry-leading quality control measures in place, FT technologies manufactures professional-grade wind sensors that are chosen for a range of demanding applications. Whether you want to upgrade your wind turbines, gain weather warnings for critical infrastructure or get accurate wind data for your autopilot, FT wind sensors ensure you receive reliable data 24 hours a day, 365 days a year.

control systems

Making precise adjustments to your equipment based on wind speed and wind direction means you need data that you can rely on. FT wind sensors bring the latest developments in software processing and aeroacoustics to give you the best performance, efficiency and reliability at all times.

navigation systems

Accurate wind data is essential for both partial and fully automated navigation systems, enhancing route optimisation, energy conservation, and safety. By integrating real-time wind speed and direction, vessels can adjust their course to minimise drag, reduce fuel consumption, and avoid hazardous conditions. With advanced wind sensors providing reliable, up-to-date information, navigation systems can make precise decisions, leading to smoother operations and lower operational costs.

safety warnings

Wind sensors are vital components of safety systems across various industries, providing real-time, accurate data on wind speed and direction. This information is crucial for preventing accidents, safeguarding structures, and ensuring safe operations in challenging environments, from construction sites to transportation networks. By enabling precise adjustments or emergency shutdowns during high winds, these sensors help maintain safety standards, minimise risks, and enhance operational reliability. Discover how FT’s advanced wind sensors deliver the critical data needed to protect lives and assets in wind-sensitive applications.

weather monitoring

Wind sensors are essential for weather monitoring applications such as air quality analysis, methane leak detection, and dynamic line rating. Accurate wind data enables the tracking of pollutant and methane dispersion, supporting effective environmental management and safety measures. For dynamic line rating, precise wind speed and direction measurements optimise power grid efficiency by calculating real-time line capacity. FT wind sensors deliver reliable, high-resolution data, ensuring dependable performance across these diverse applications.

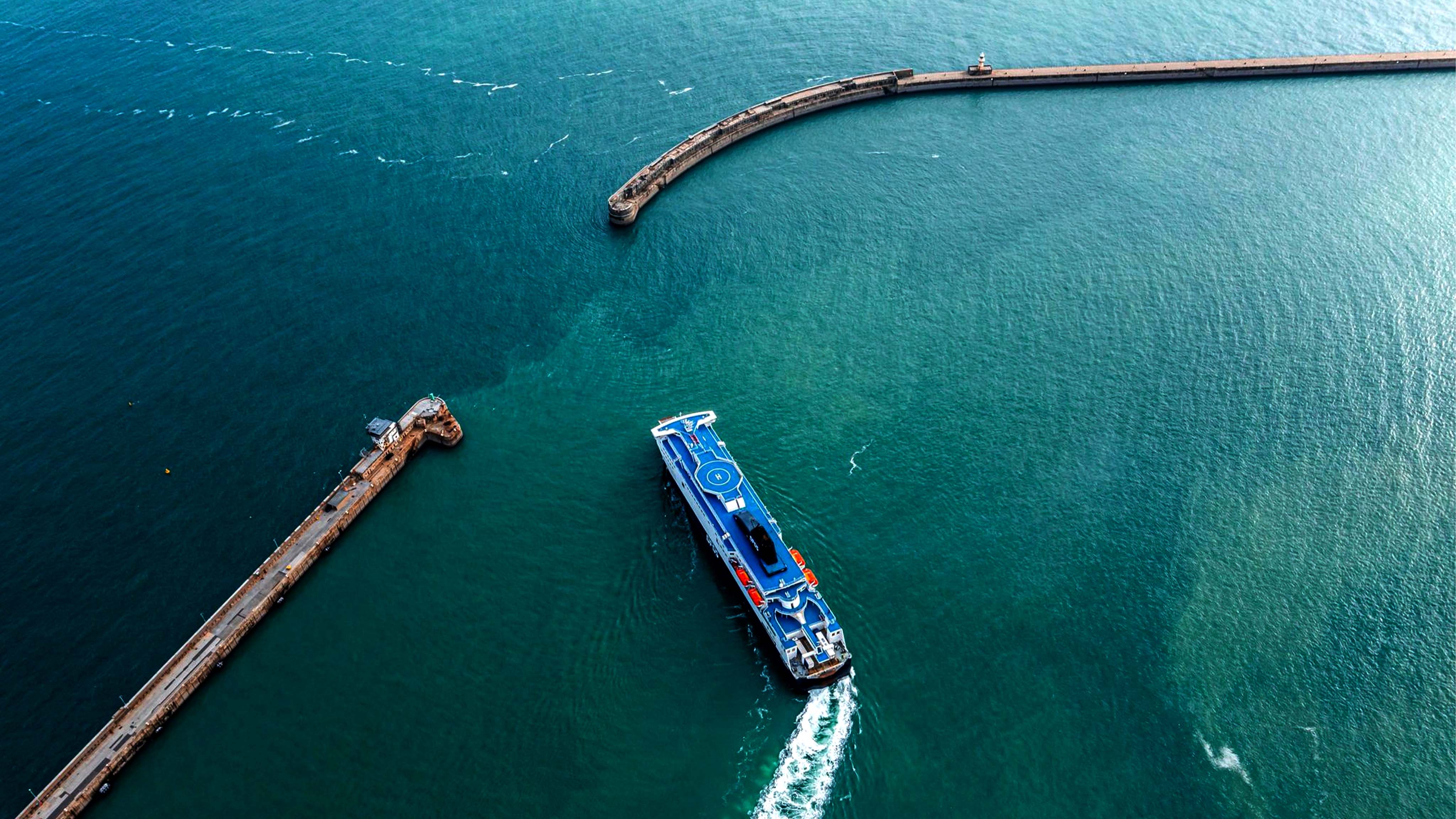

marine

Wind sensors are indispensable in marine environments, providing accurate wind speed and direction data critical for safety, efficiency, and performance. On commercial ships, they optimise navigation and enhance operational safety, even in harsh oceanic conditions. For offshore buoys, wind sensors deliver essential weather and ocean monitoring data, enduring constant exposure to saltwater and rough seas. In performance sailing, they offer the precision needed for tactical decisions while withstanding the physical stresses of racing. FT’s durable, corrosion-resistant wind sensors are engineered to deliver reliable, maintenance-free operation in demanding marine environments, ensuring consistent data across all applications.